apqp manual

The APQP manual provides guidance on product quality planning,

including

tools and techniques for ensuring high-quality products, with a focus on customer requirements and expectations, using a methodology that originated in the automotive industry effectively always.

Purpose of APQP

The purpose of APQP is to provide a structured approach to product quality planning, with the goal of ensuring that products meet customer requirements and expectations. This is achieved through a series of steps and tools, including planning, design, development, and production. The APQP methodology is designed to be flexible and adaptable, allowing it to be applied to a wide range of products and industries. By using APQP, organizations can improve the quality of their products, reduce the risk of defects and errors, and increase customer satisfaction. The APQP manual provides guidance on how to implement this methodology, including the use of tools such as control plans, failure mode and effects analysis, and measurement systems analysis. Overall, the purpose of APQP is to provide a framework for ensuring that products are designed and produced to meet customer needs and expectations, and to continually improve the quality of those products over time. This approach has been widely adopted in the automotive industry and is now being used in other industries as well, including aerospace and healthcare.

History of APQP

The APQP manual originated in the automotive industry, with a focus on quality planning, using a methodology that has been developed over time to ensure high-quality products effectively always with new updates and revisions added.

Evolution of APQP

The evolution of APQP has been significant, with updates and revisions added to the manual over time to reflect changes in the industry and best practices.

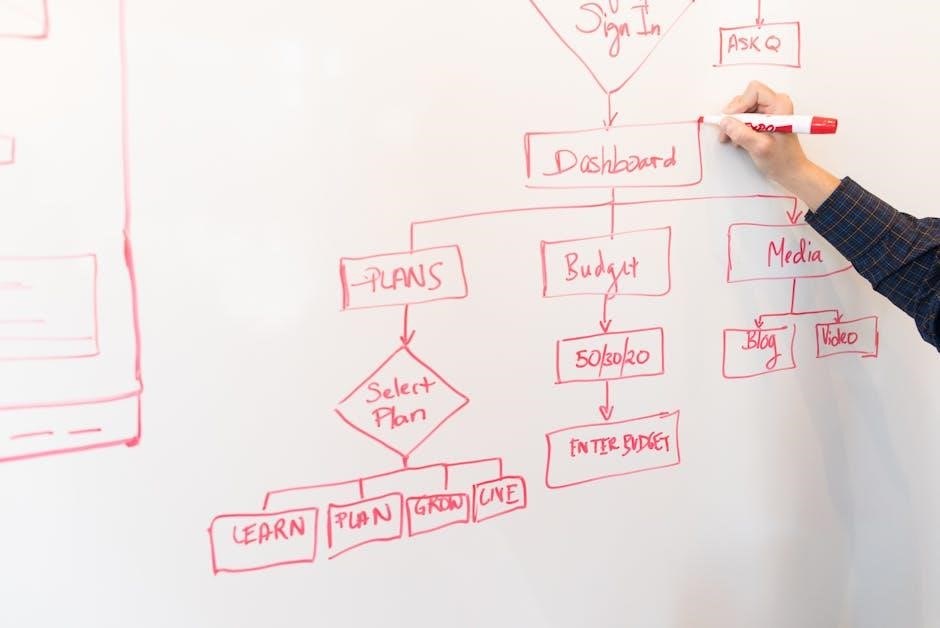

The methodology has been refined to include new tools and techniques, such as agile product management and gated management, to improve the efficiency and effectiveness of the quality planning process.

The APQP manual has also been updated to reflect the increasing importance of sourcing, change management, and risk assessment, with new sections and guidance added to address these areas.

Additionally, the manual has been revised to include new information on part traceability and other relevant topics, to ensure that it remains a comprehensive and authoritative guide to quality planning.

The evolution of APQP is an ongoing process, with new developments and advancements being incorporated into the methodology on a regular basis, to ensure that it continues to meet the needs of industry and remains a valuable resource for organizations seeking to improve their quality planning processes.

The APQP manual is widely used in the automotive industry and other sectors, and its evolution has helped to establish it as a leading methodology for quality planning and product development.

Key Components of APQP

APQP includes planning, control, and verification

steps

to ensure product quality and customer satisfaction always effectively using various tools and techniques.

Benefits of APQP

The APQP manual provides several benefits to organizations, including improved product quality and reduced defects, which can lead to increased customer satisfaction and loyalty. By following the APQP methodology, companies can ensure that their products meet customer requirements and expectations, resulting in reduced warranty claims and recalls. Additionally, APQP can help organizations to reduce costs associated with rework and scrap, and improve their overall efficiency and productivity. The use of APQP can also lead to improved communication and collaboration among teams, and provide a framework for continuous improvement and innovation. Overall, the benefits of APQP can have a significant impact on an organization’s bottom line and reputation, making it an essential tool for companies that want to stay competitive in today’s global market. By implementing APQP, companies can demonstrate their commitment to quality and customer satisfaction, and establish themselves as leaders in their industry. APQP is a valuable resource for any organization looking to improve its product quality and processes.

APQP Manual Updates

New editions of the APQP manual are released periodically, incorporating updates and revisions to reflect changes in industry practices and standards, ensuring the manual remains relevant and effective always and everywhere online.

APQP Manual Editions

The APQP manual has undergone several updates and revisions, resulting in multiple editions being released over the years. Each new edition incorporates changes and improvements to the methodology, reflecting the evolving needs of the industry. The latest edition of the APQP manual is designed to provide a more comprehensive and effective approach to product quality planning, with a focus on agile product management and Industry 4.0 practices. The updates include new sections on sourcing, change management, and risk assessment mitigation plans, as well as revised content on part traceability and gated management. The APQP manual editions are widely used in the automotive and other industries, providing a standardized approach to product quality planning and ensuring that products meet customer requirements and expectations. The editions are available for download, and users can access the latest version through online platforms, ensuring that they have access to the most up-to-date information and guidance on APQP methodology. The APQP manual editions are an essential resource for companies seeking to improve their product quality planning processes.

The APQP manual provides effective product quality planning, using a methodology that ensures high-quality products, with a focus on customer requirements and industry standards always and effectively in the industry every day.

Future of APQP

The future of APQP looks promising, with ongoing updates and revisions to the manual, incorporating new technologies and methodologies to improve product quality planning.

The APQP manual is expected to continue playing a crucial role in ensuring high-quality products, with a focus on customer requirements and industry standards.

As the industry evolves, the APQP manual will likely incorporate new concepts, such as artificial intelligence and machine learning, to enhance product quality planning.

The use of digital tools and platforms will also become more prevalent, enabling more efficient and effective implementation of APQP principles.

Additionally, the APQP manual will continue to be widely adopted across various industries, beyond its origins in the automotive sector.

Overall, the future of APQP is exciting, with opportunities for growth, innovation, and improvement in product quality planning, and its impact on the industry will be significant.

With its commitment to excellence and customer satisfaction, the APQP manual will remain a vital resource for organizations seeking to improve their product quality planning capabilities.

The ongoing development and refinement of the APQP manual will ensure its continued relevance and effectiveness in the years to come.

As a result, the future of APQP is bright, with a continued focus on delivering high-quality products that meet customer requirements and expectations.